- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

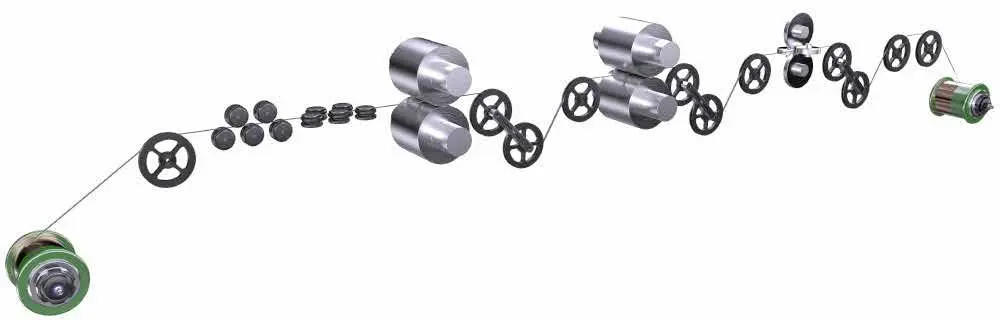

Isigayo sokugibela isicaba

Njengomenzi wemishini ephezulu yezobuchwepheshe obuphakeme, i-Hmpproling ihlinzeka ngezindlela eziningi zokuqamba eziphezulu eziphezulu zokukhiqiza unxande, isikwele kanye nephrofayli geometries. Ubuchwepheshe bomshini wombuso-wobuciko buqinisekisa isikhathi sokuphumula esincane kanye nokuphuma okuphezulu.

Ngokusekelwe ebangeni lethu elijwayelekile, imishini yenziwe ngokwezifiso ekubhekeni amakhasimende nezidingo zezinto ezibonakalayo.

Ukugoqa okusicaba nokugingqa iphrofayili

Kule nqubo, izintambo eziyindilinga zigibela zibe fat kanye / noma geometries ekhethekile ebunjiwe. Ngesikhathi senqubo, ucingo lugingqika ngezigaba eziningana zibheke ngokuqondile nangokuvundlile (ukugoqa onqenqemeni). Uhla olukhulu lwamaphrofayili ahlukene luyasebenza.

Ukucushwa:

| Uhlobo lwe-Mill | Fpw 9o | FPW 200 | Fpw 400 | Fpw 600 | Fpw8o0 | FPW 1000 | I-FPW1200 | |

| 2Hi roll usets | I-Rolling Force [kn] | 90 | 200 | 400 | 600 | 800 | 1000 | 1200 |

| I-roll ububanzi / 1 [mm] | 80 | 140 | 180 | 240 | 280 | 340 | 380 | |

| Roll ububanzi / 2 [mm] | 100 | 160 | 200 | 260 | 300 | 360 | 400 | |

| I-roll ububanzi / 3 [mm] | 120 | 180 | 220 | 280 | 320 | 380 | 420 | |

| Roll ring ububanzi [mm] | 60 | 80 | 150 | 150 | 150 | 200 | 200 | |

| Uhlobo lwe-Mill | Em 30 | Em 60 | Em 100 | Em 120 | |

| Umkhawulo roll | I-Rolling Force [kn] | 30 | 60 | 100 | 120 |

| I-roll ububanzi / 1 [mm] | 70 | 110 | 150 | 190 | |

| Roll ububanzi / 2 [mm] | 80 | 120 | 160 | 200 | |

| I-roll ububanzi / 3 [mm] | 90 | 130 | 170 | 210 | |

| Roll ring ububanzi [mm] | 40 | 80 | 80 | 100 | |

Izakhiwo nezici:

Umshini womshini we-modular onwebekayo

Ukucaca okuphezulu kwe-servo-mechanic screw phansi

I-Ricid and Heavy-Duty Roll Stand

Ukuthunyelwa okuzenzakalelayo okuzenzakalelayo

Mill drill njenge-mono ne-twin drive ngebanga lesivinini eliguquguqukayo

Ama-roll atholakala ngohlobo lwensimbi ekhethwe, i-HSS noma nge-tungsten carbide ring

Imishini etholakala ngohlobo oluhlukile lokuthambisa (ukukhulisa isikhukhula noma ukuthambisa okuncane)

Ubukhulu bokunemba okuphezulu nokulinganiswa kobubanzi - Ukuxhumana nama-Gauges we-laser

Uhla oluphelele lwezinhlelo zokufaka umoya

Ukulawulwa kokungezwani kwe-wire ngokusebenzisa i-dancer accumulator, umdansi, i-capstan kanye ne-candepillar

Ukuqedwa komhlaba okuqediwe nokuhlanza

Izinhlelo zesoftware nezinhlelo zokulawula:

Uhlelo lokulawula lwedijithali ngokuphelele kanye nokuxilonga

Ukubalwa kwangaphambili nokugcina amashejuli okudlula

Ukusetha Komshini Ozenzakalelayo Ngokuzenzakalelayo

Ukuqashwa kwama-torque, izinga lokushisa, amandla okulungiswa kanye nokungezwani kwe-wire

I-Fels Edge Serve - Isinyathelo Sakho Emboni 4.0

Ubukhulu obusebenzayo kanye nomthethonqubo wobubanzi

Inkambiso nokulawulwa kwe-cascade

Idizayini yomshini we-modular:

Kulula ukulondolozwa:

Izinguquko ezizenzakalelayo ezizenzakalelayo

Uhlelo oluphakathi lwe-lubrication

Isexwayiso sokubikezela kwesimo somshini esibucayi

Ukuvikelwa Okubanzi Ka-Electronic

Design Variants:

I-Spindle Or Flange Cooling Technology Kanye nama-mandrels asabalazayo we-coreling

Inani lama-flat wire rolling mills linganwetshwa ngokungenamkhawulo kumklamo wokuma komshini we-modular

I-Dancer Accumulator kanye nomdansi ku-servo design yezinhlelo zokusebenza ezinamandla kakhulu

Ama-Roll Engaqhutshwa Noma aqhutshwa

Izinhlelo zokuqondisa ze-wire ezinobuhlakani zokusetha komshini okulula nokulawulwa kwenqubo

- View as

I-Electromagnetic Wire Rolling Mill

I-Electromagnetic Wire Rolling Mill yohlobo lwemishini esetshenziselwa ukucubungula ucingo lwensimbi lube ngocingo lwe-electromagnetic. Isetshenziselwa ikakhulukazi ukukhiqiza imininingwane ehlukahlukene ye-electromagnetic flat wire. Isetshenziswa kabanzi ku-wire nekhebula, izingxenye zezimoto, ama-elekthronikhi kanye nezinye izinkambu.

Funda kabanziThumela UphenyoI-Photovoltaic Welding strip rolling mill

I-Photovoltaic Welding strip rolling mill ekhiqizwa yiFlat Wire Workill ngumkhiqizo okhethekile we-Flat Wire umkhiqizo osetshenziselwa ukuxhuma amaseli e-solar kumamojula we-photovoltaic. Ihlanganiswe ne-substrate yethusi kanye nenhlanganisela engaphezulu. I-Copper Substrate imvamisa i-Oflygen Free Copper noma i-T2 Red Copper, nokuqukethwe kwethusi ≥ 99.99% kanye nokwenza u-98%. Inokuqhutshwa okuhle namandla athile, angaqinisekisa ukuhanjiswa okusebenzayo kwamanje.

Funda kabanziThumela Uphenyo